Smart Maintenance: AI’s Impact on Heavy Machinery

Heavy machinery forms the backbone of critical industries such as construction, mining, agriculture, and logistics. However, ensuring their optimal performance and longevity has traditionally been fraught with challenges. The prevalent maintenance paradigms – reactive (fix-on-fail) and time-based (scheduled) – often lead to significant operational inefficiencies.

Traditional Maintenance Challenges and AI’s Disruptive Potential

- Reactive Maintenance: Repairs are initiated only after a breakdown occurs, resulting in costly unscheduled downtime, production losses, and higher emergency repair expenses.

- Time-Based Maintenance: Components are replaced at fixed intervals, often leading to premature replacements and material waste, or conversely, failing to prevent unexpected failures between scheduled checks.

- Inefficient Manual Inspections: Highly reliant on human experience, manual checks are prone to subjectivity, human error, and struggle to cover all potential risks efficiently.

- Data Silos: Sensor data, repair logs, and operational records are often disparate, making it challenging to gain a holistic view of equipment health.

Artificial Intelligence (AI) is emerging as a powerful disrupter, offering a paradigm shift from “curing ailments” to “preventing illnesses.” By leveraging AI, heavy machinery maintenance can become more proactive, precise, efficient, and cost-effective.

Core Applications of AI in Heavy Machinery Maintenance Today

AI’s integration into heavy machinery maintenance is already yielding tangible benefits across several key areas:

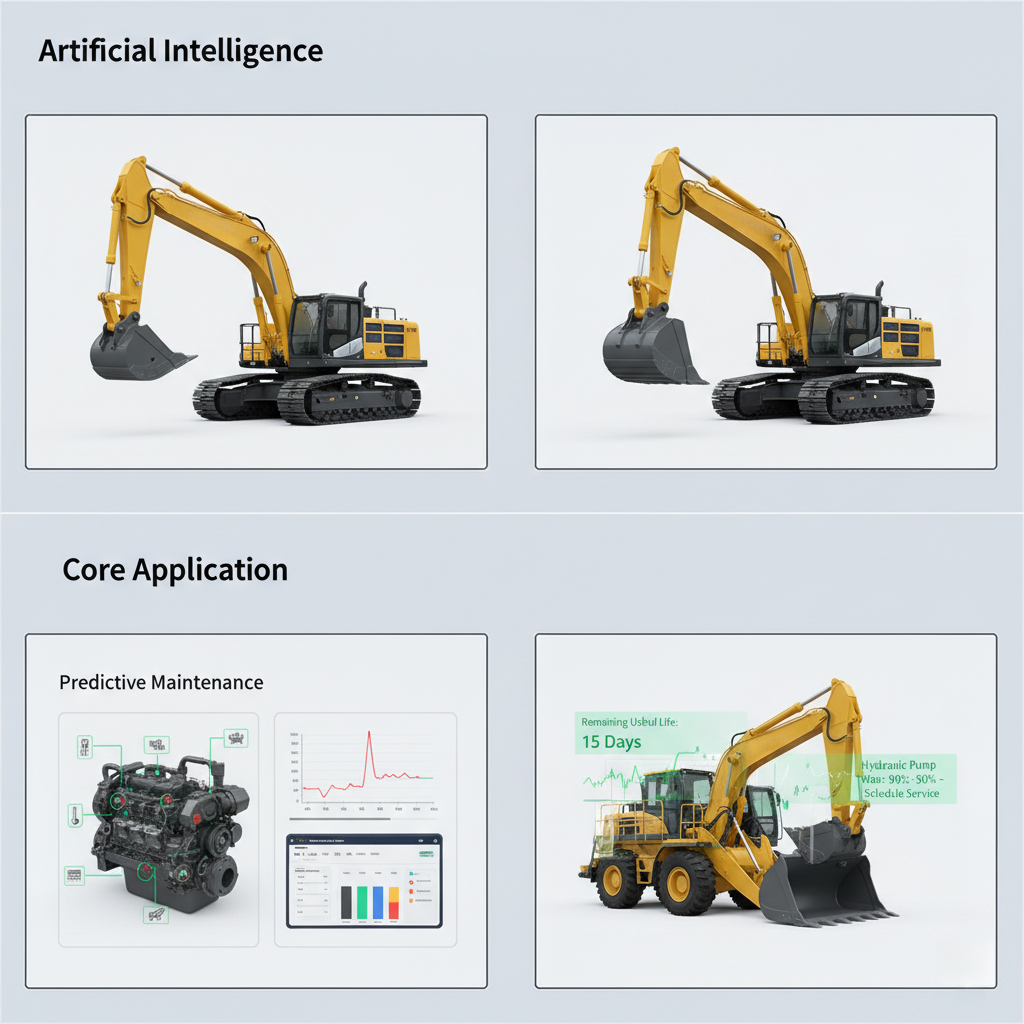

Predictive Maintenance (PdM) – AI’s Most Mature Application

Predictive maintenance is at the forefront of AI applications, enabling the foresight to anticipate equipment failures before they happen.

- Data Acquisition & Pre-processing:

- Sensor Networks: Deployment of various sensors (vibration, temperature, pressure, acoustic, oil analysis) on critical machinery components.

- Data Types: Collection of diverse data including time-series, image, and textual data (maintenance logs).

- Data Cleansing & Feature Engineering: Advanced techniques to handle noise, missing values, and extract meaningful features (e.g., spectral features from FFT transforms).

- Machine Learning Models:

- Anomaly Detection: Employing models like Isolation Forests, SVM, and neural networks to identify deviations from normal operating patterns.

- Fault Prediction: Using sequence models such as LSTMs or GRUs, or ensemble learning methods, to predict the Remaining Useful Life (RUL) of components and forewarn potential failures based on historical and real-time data.

- Fault Classification & Diagnosis: Upon detecting an anomaly, AI models can rapidly identify the type of fault (e.g., bearing wear, gear tooth fracture, hydraulic leak) and pinpoint the affected component.

- Decision Support & Actionable Recommendations: Based on predictive analytics, the system automatically generates prioritized maintenance schedules and suggests optimal intervention timings and procedures.

- Examples: Engine fault prediction in mining trucks, hydraulic pump life prediction in excavators.

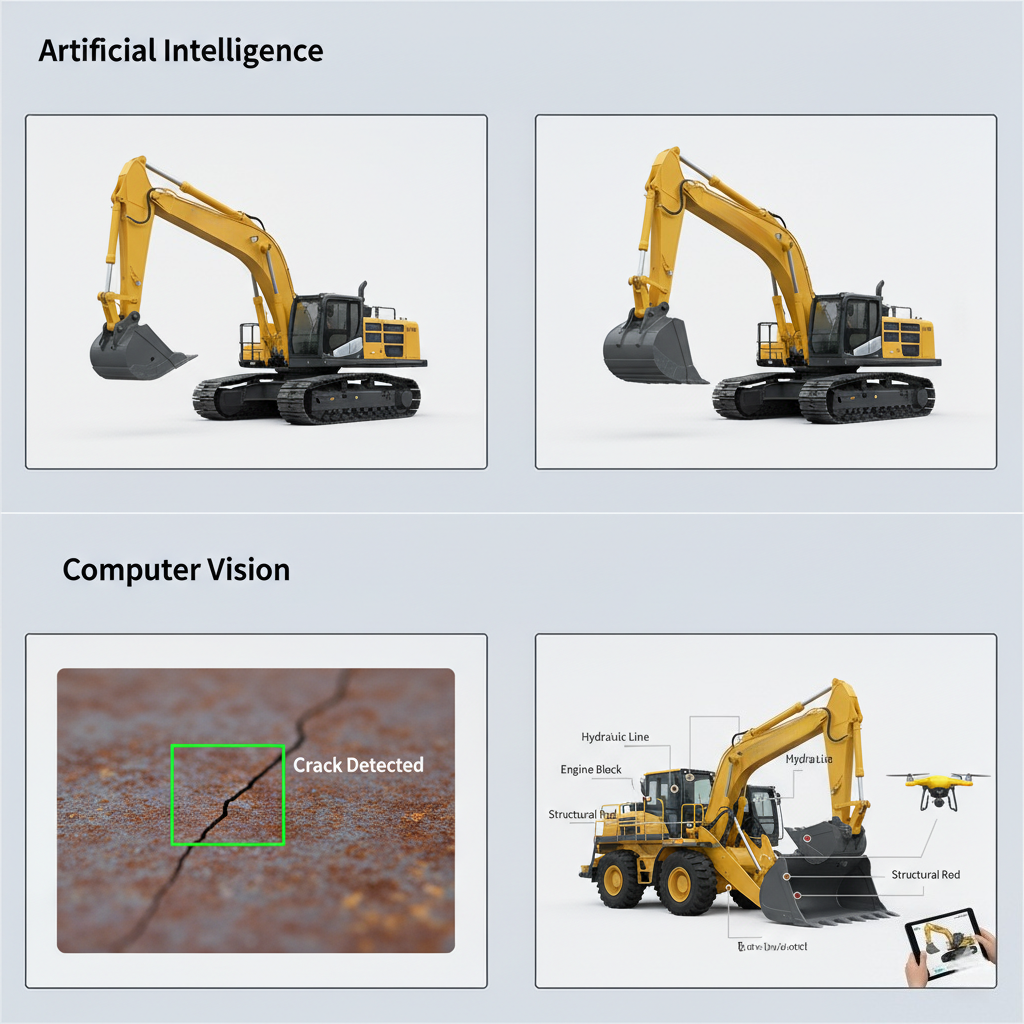

Computer Vision (CV) for Visual Inspection

Computer Vision significantly enhances the accuracy and efficiency of visual inspections, particularly for large-scale or intricate machinery.

- Defect Detection: Leveraging deep learning (Convolutional Neural Networks – CNNs) to automatically identify subtle defects like cracks, wear, corrosion, or deformation on machinery surfaces that are hard to spot manually or require extensive time.

- Component Recognition & Counting: Automating the identification and inventorying of parts in stock management or assembly processes.

- Drone/Robot-Based Inspections: Integrating drones or ground robots equipped with high-resolution cameras and AI algorithms for autonomous inspections of large equipment, especially in elevated, hazardous, or hard-to-reach areas.

- Examples: Track shoe wear detection, structural component surface crack identification.

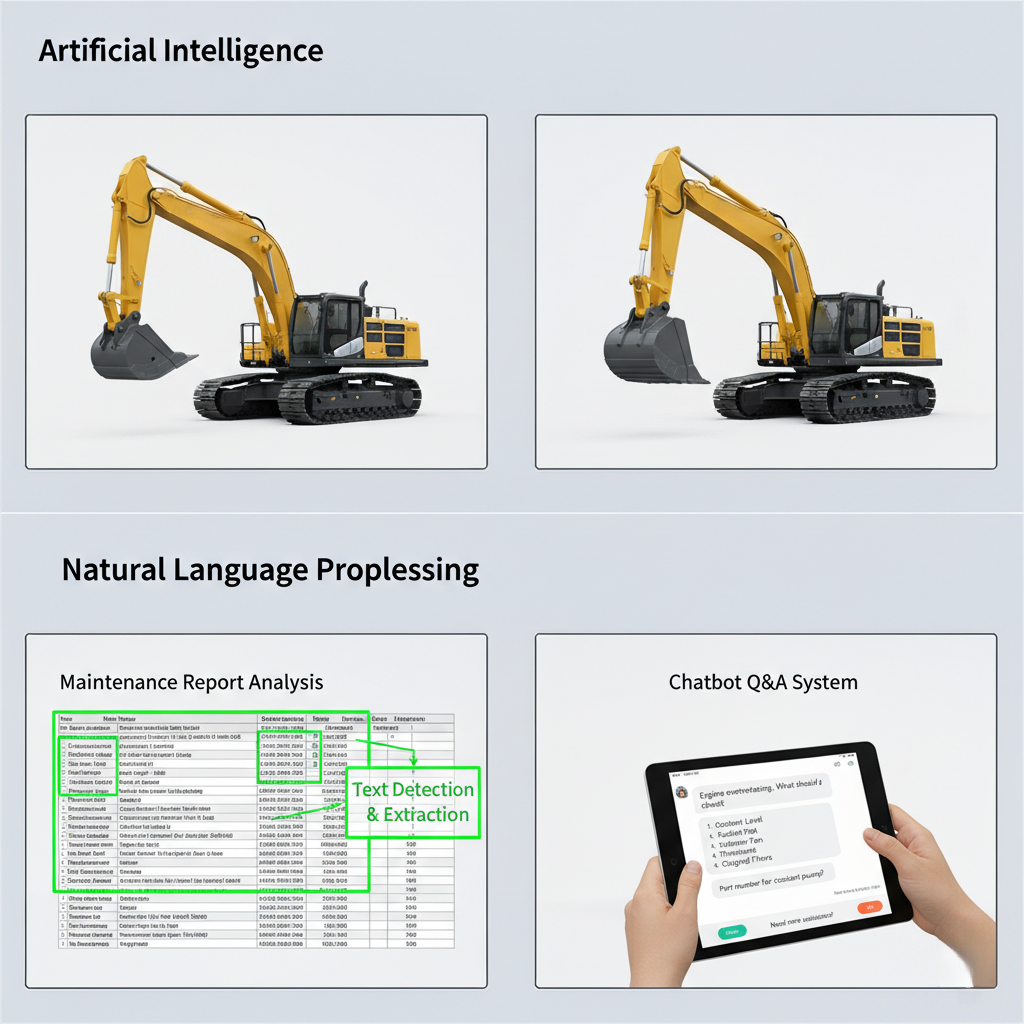

Natural Language Processing (NLP) for Knowledge Management

NLP extracts valuable insights from unstructured textual data, transforming vast amounts of information into actionable knowledge.

- Maintenance Report Analysis: Automatically extracting critical information such as fault symptoms, repair actions, and replaced parts from unstructured repair logs and operator reports, aiding in knowledge graph construction and optimized fault diagnosis.

- Intelligent Q&A Systems/Chatbots: Providing technicians with instant access to troubleshooting guides, parts lookup, and maintenance manuals, significantly improving service efficiency.

- Examples: Identifying recurring hidden fault patterns from extensive maintenance work orders.

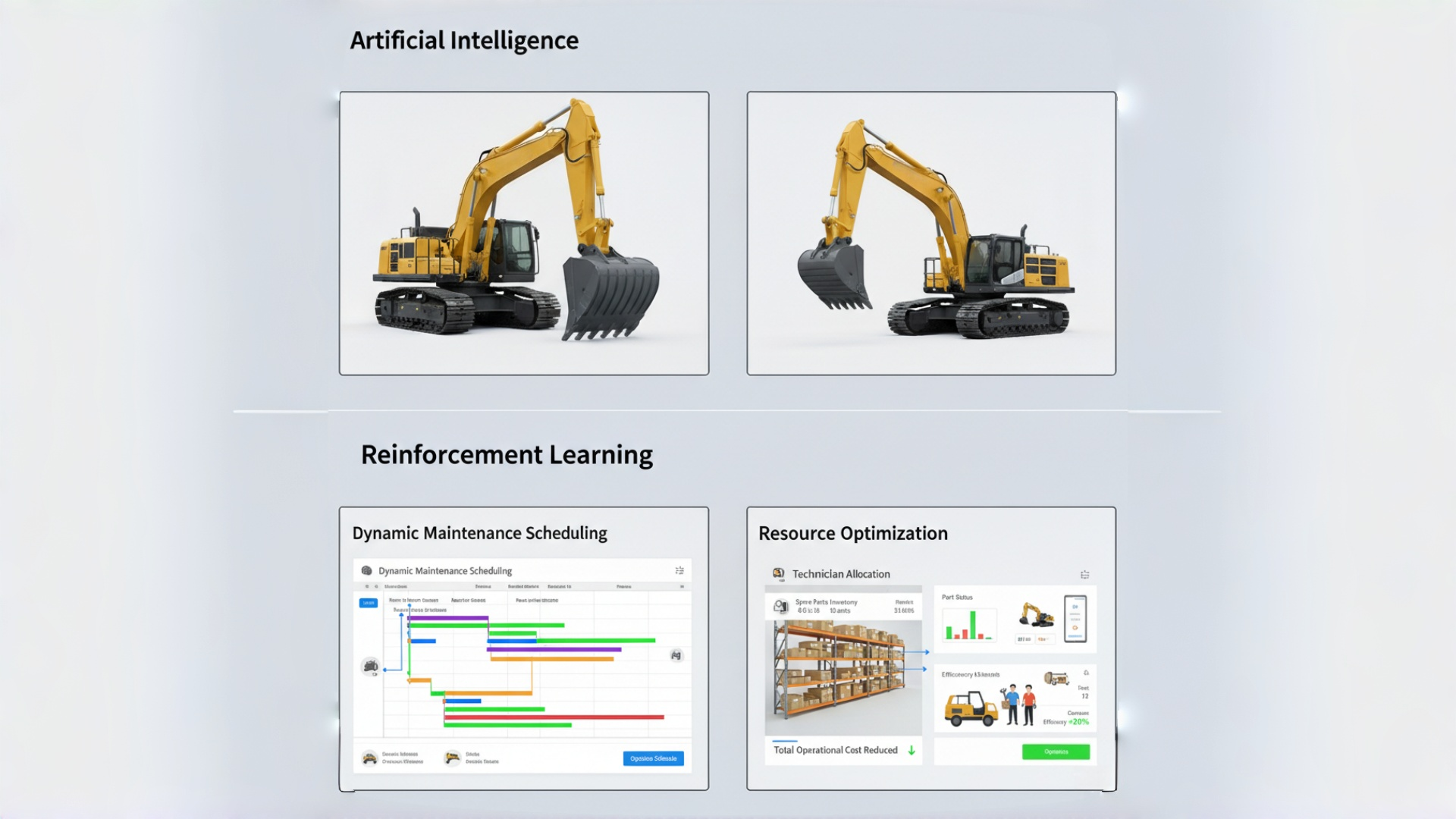

Reinforcement Learning (RL) for Optimization Strategies

RL offers a dynamic approach to optimizing complex maintenance processes by learning from interactions within an environment.

- Dynamic Maintenance Scheduling: Based on real-time equipment status, resource availability, and cost-benefit analysis, RL can learn and generate optimal maintenance scheduling strategies.

- Resource Optimization: Intelligently recommending optimal spare parts inventory levels and technician allocation, thereby reducing overall operational costs.

- Examples: Global maintenance strategy optimization for a fleet of heavy equipment.

Value and Benefits of AI-Powered Heavy Machinery Maintenance

Embracing AI in maintenance delivers a multitude of strategic advantages:

- Significant Reduction in Downtime: Proactive interventions minimize unscheduled stops, drastically increasing equipment availability.

- Extended Equipment Lifespan: Precision maintenance reduces unnecessary wear and tear, optimizing component utilization.

- Lower Maintenance Costs: Reduced spare parts wastage, optimized labor allocation, and avoidance of expensive emergency repairs contribute to substantial cost savings.

- Enhanced Operational Efficiency & Safety: Streamlined maintenance workflows lead to more reliable equipment operation and fewer safety incidents.

- Data-Driven Decision Making: Management gains access to more scientific and quantifiable insights for strategic planning.

- Improved Customer Satisfaction: More stable and reliable equipment operation builds stronger customer trust and loyalty.

Future Outlook – Cutting-Edge Trends in AI for Heavy Machinery Maintenance

The evolution of AI continues to open new frontiers in maintenance, promising even more sophisticated and integrated solutions:

- Deep Integration of AI with Edge Computing:

- Localized Intelligence: Real-time data processing and preliminary analysis directly on the equipment, reducing latency and bandwidth requirements for cloud transmission.

- Rapid Response: Equipment can react more swiftly to emergent situations.

- Data Privacy Protection: Sensitive data can be processed locally, enhancing security.

- Synergy of Digital Twins and AI:

- Full Lifecycle Management: Creation of virtual digital models for each physical machine, mirroring its real-time operational status, historical data, and maintenance records.

- High-Precision Simulation & Prediction: AI models are trained and validated within the digital twin, enabling ultra-precise predictions of future equipment behavior and fault simulations.

- Visualized Operations & Maintenance: Digital twin platforms offer intuitive visualization of equipment health and performance.

- Multi-Modal Data Fusion and Complex System Diagnostics:

- Integration of Diverse Sensor Data: Combining heterogeneous data from vibration, temperature, acoustic, oil analysis, images, and even operator voice to build a more comprehensive equipment health profile.

- Cross-System Intelligence: Beyond individual component diagnosis, AI will analyze interdependencies between multiple subsystems to resolve complex system-level failures.

- Human-Machine Collaboration with Augmented Reality (AR)/Virtual Reality (VR) Integration:

- AR-Assisted Maintenance: Technicians wearing AR glasses can receive real-time AI-generated fault diagnostics, step-by-step repair instructions, and 3D models, significantly improving repair efficiency and accuracy.

- Remote Expert Support: AI systems can act as a bridge, connecting on-site personnel with remote experts for intelligent assistance.

- Adaptive and Self-Learning Systems:

- Continuous Model Optimization: AI models will continuously learn and refine themselves based on new operational data and maintenance feedback, adapting to equipment aging and changing operating conditions.

- No-Code/Low-Code Platforms: Lowering the technical barrier for AI adoption, enabling more businesses to autonomously develop and deploy intelligent maintenance solutions.

Challenges and Solutions for Implementing AI Maintenance

While the benefits are clear, implementing AI in heavy machinery maintenance presents its own set of challenges:

- Data Quality & Quantity: Ensuring the completeness, accuracy, and representativeness of data.

- Solution: Improve sensor deployment, establish unified data platforms, and enforce strict data collection protocols.

- Model Generalization Capability: The applicability of models across different equipment types and operating conditions.

- Solution: Employ techniques like transfer learning and federated learning, and build diverse datasets.

- IT/OT Convergence: Integrating operational technology (OT) systems with information technology (IT) systems.

- Solution: Foster cross-departmental collaboration, adopt open standards and protocols.

- Talent Shortage: A scarcity of professionals with combined expertise in machinery and AI.

- Solution: Internal training programs, strategic hiring, and partnerships with academic institutions.

- Return on Investment (ROI) Period: The initial investment can be substantial, requiring clear ROI assessments.

- Solution: Start with small-scale pilot projects, gradually expand, and meticulously quantify benefits.

We believe that embracing this shift towards smart maintenance is not just an option, but a strategic imperative for securing long-term operational excellence and market leadership.